Troubleshoot Guide

A bandsaw blade is a cutting tool and ultimately tool life is defined by machine tools and the skill of the operators. Kindly see the effect of five different relations of the blade to enhance its life.

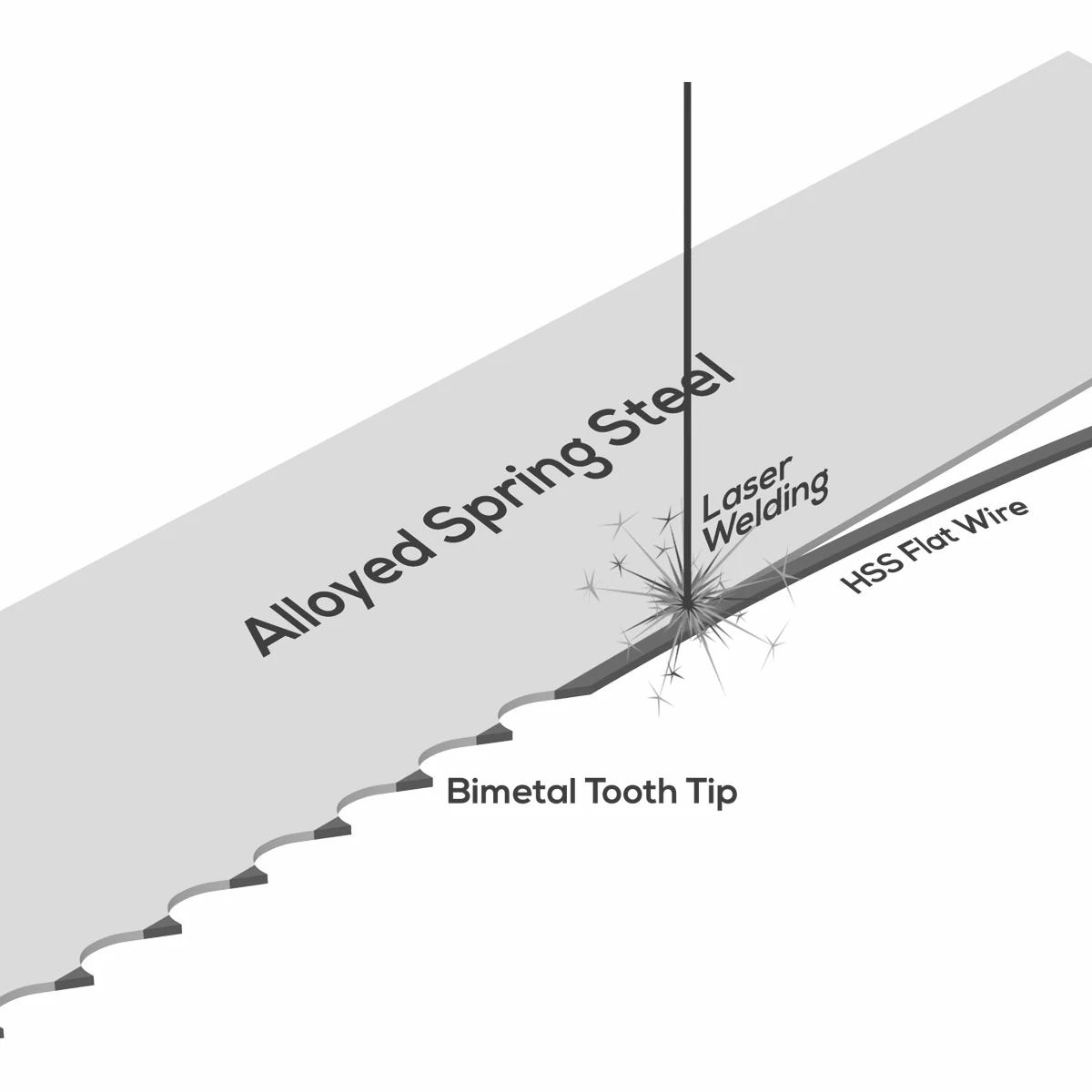

Bimetal is composed of two metals fused together. In the case of the sawblades, the backup steel is composed of high alloy steel and the cutting edge is of M42 (8% cobalt) OR M51 (10% Cobalt), welded using our proprietary Laser welding system. (please insert corrections/ additions)

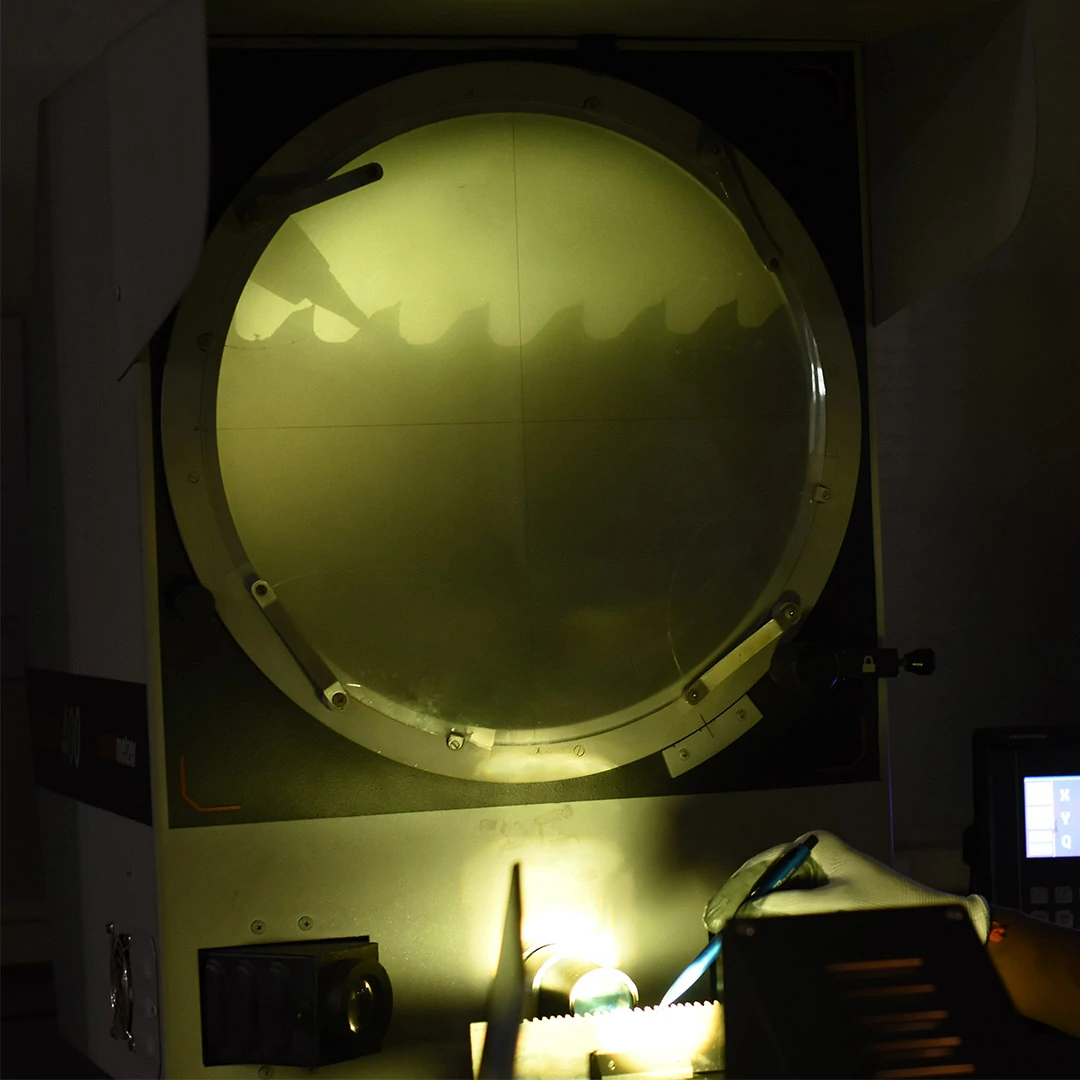

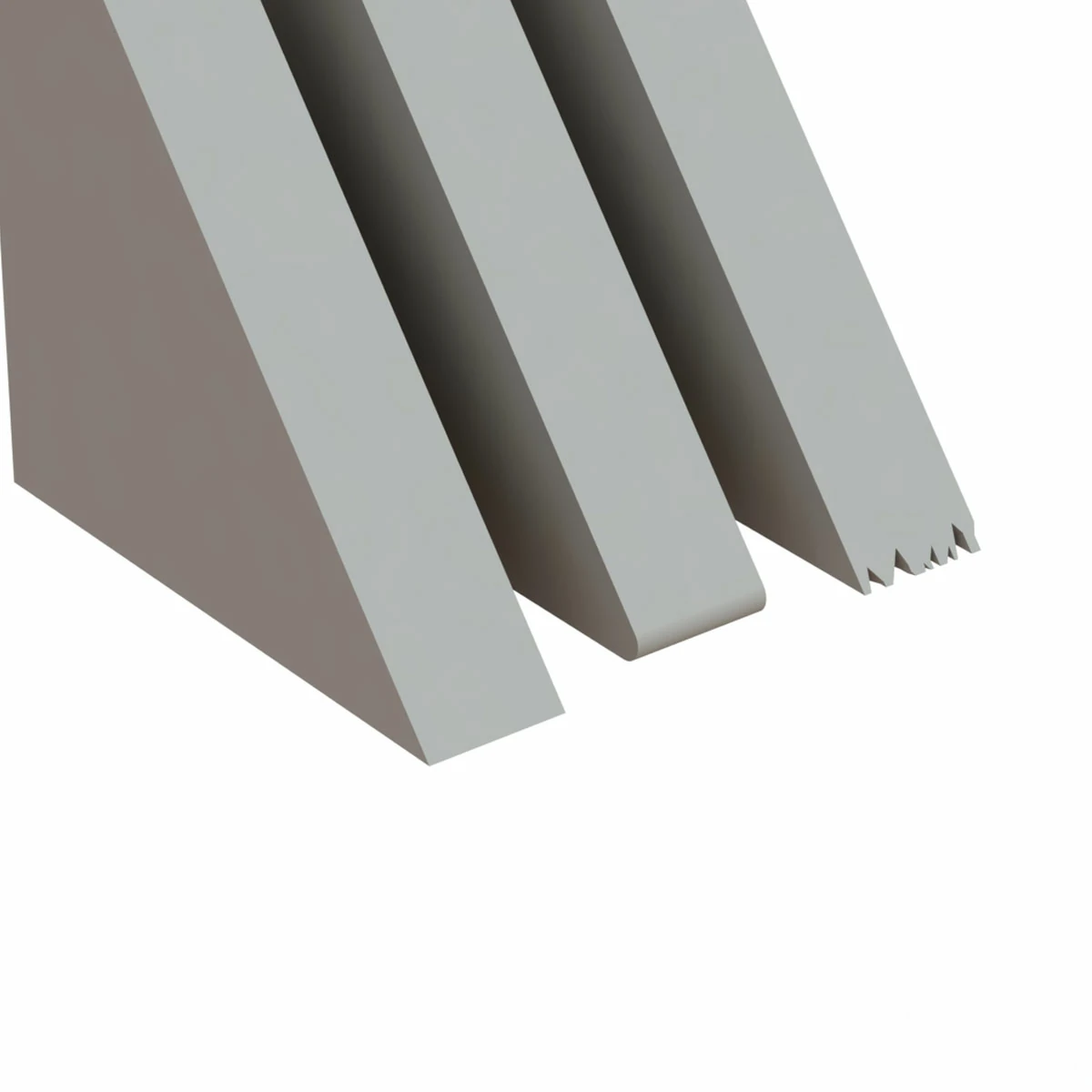

We have inhouse R&D setup for establishing unique tooth geometry for specific cutting applications. Milling of our saws are basically based on those geometries.

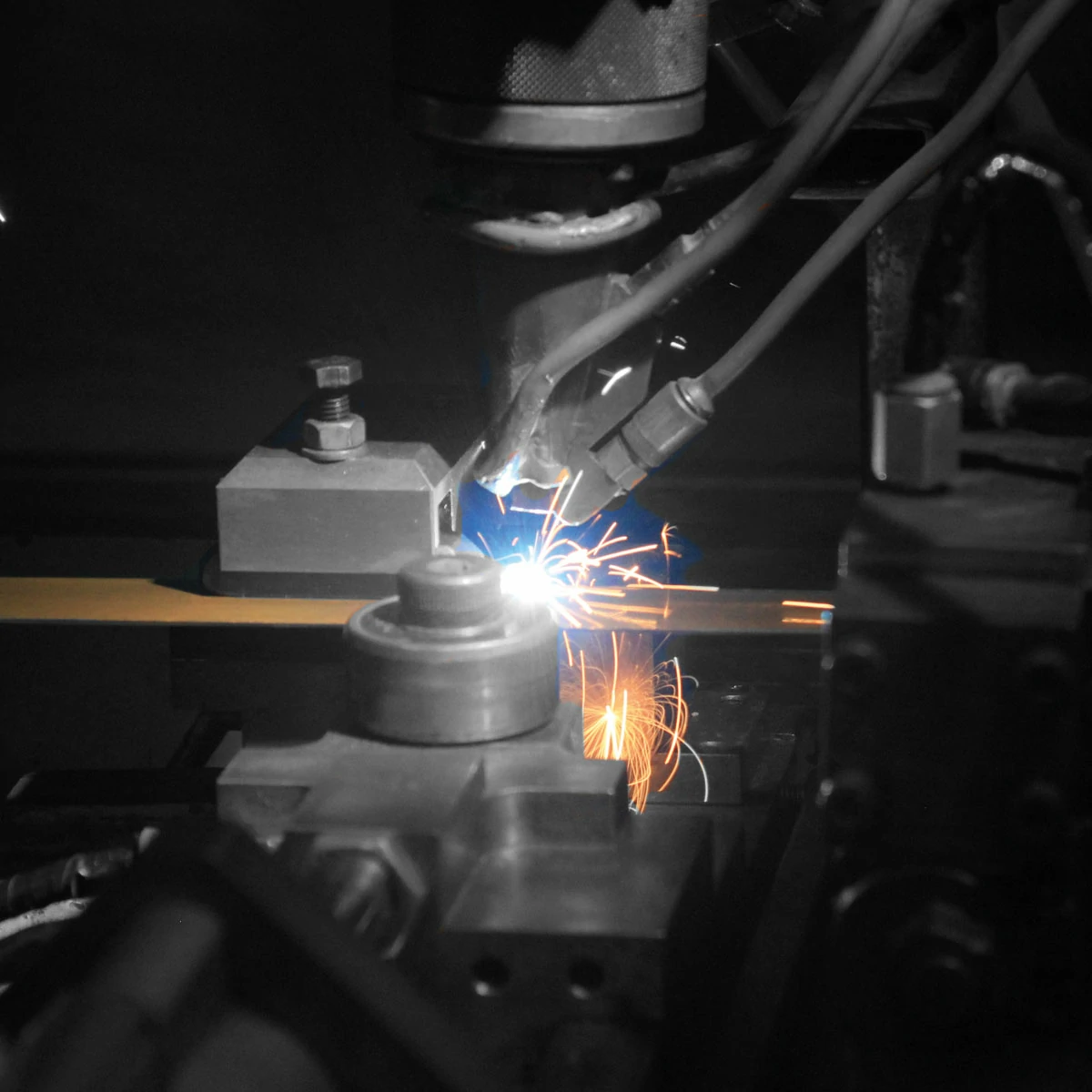

This is the most critical process, involving the chemical bonding of 2 dissimilar metals through laser technology. We have succeeded in developing and operating the laser welding process for welding HSS wire to suitable backing steel.

Quality is in our ethos and we have in place a careful quality control paradigm through the input and output stages, to assure consistency and quality to our customers.

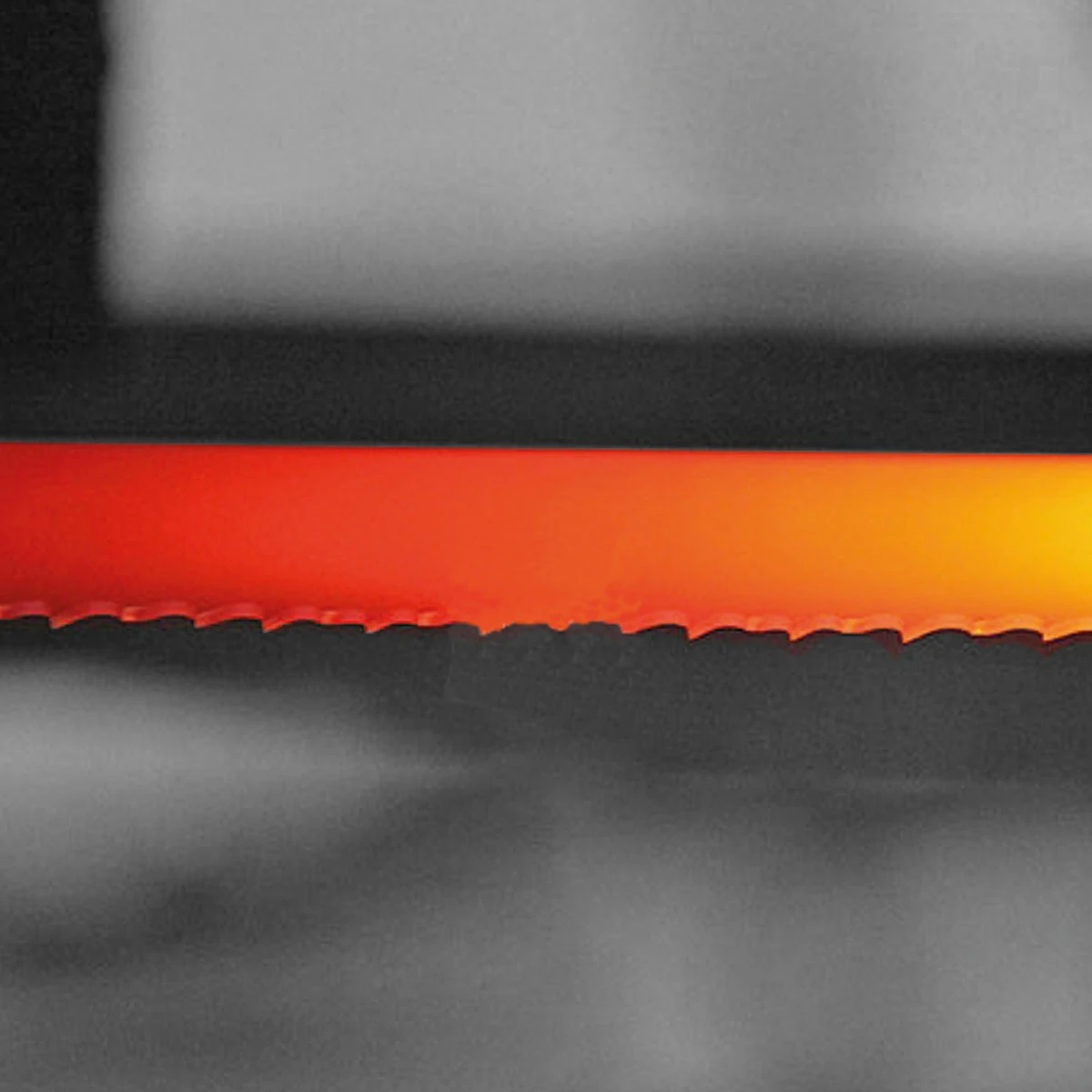

Heat treatment is always the heart of a cutting tool. We have developed special continuous heat treatment process for our saws in very controlled atmosphere furnace. The rate of heating, soaking and rate of quenching is fully controlled by digital programming to have best homogenous and consistent micro structures in the tool.

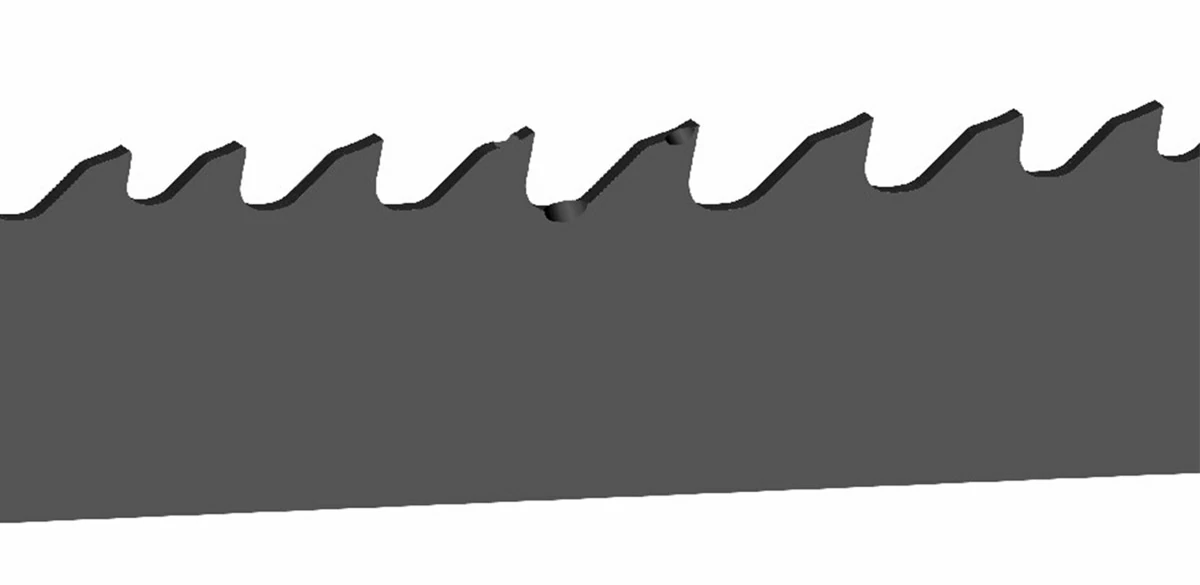

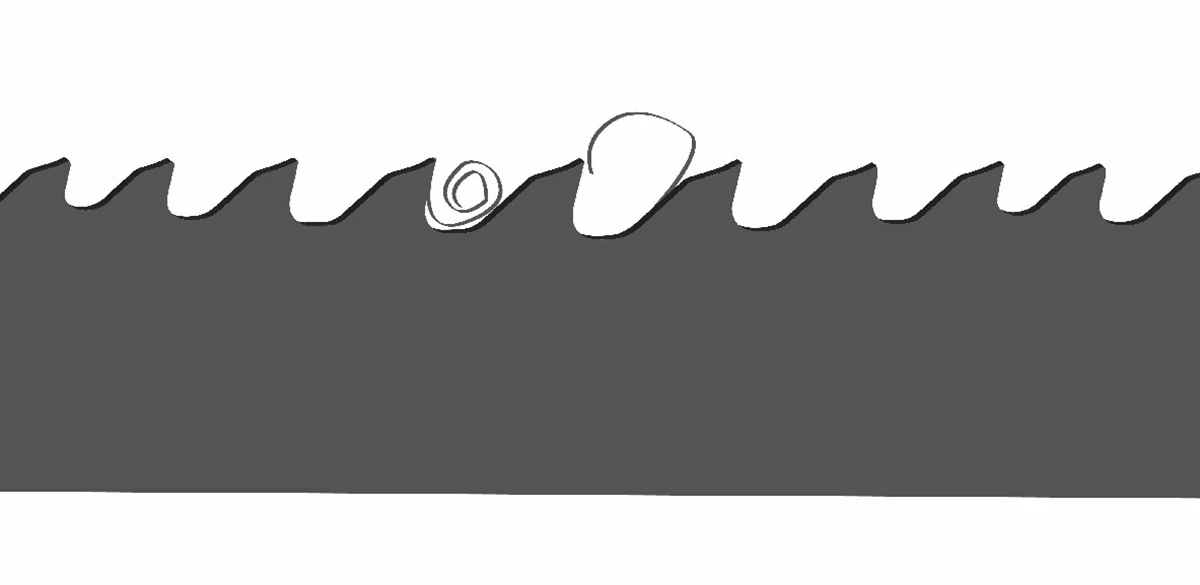

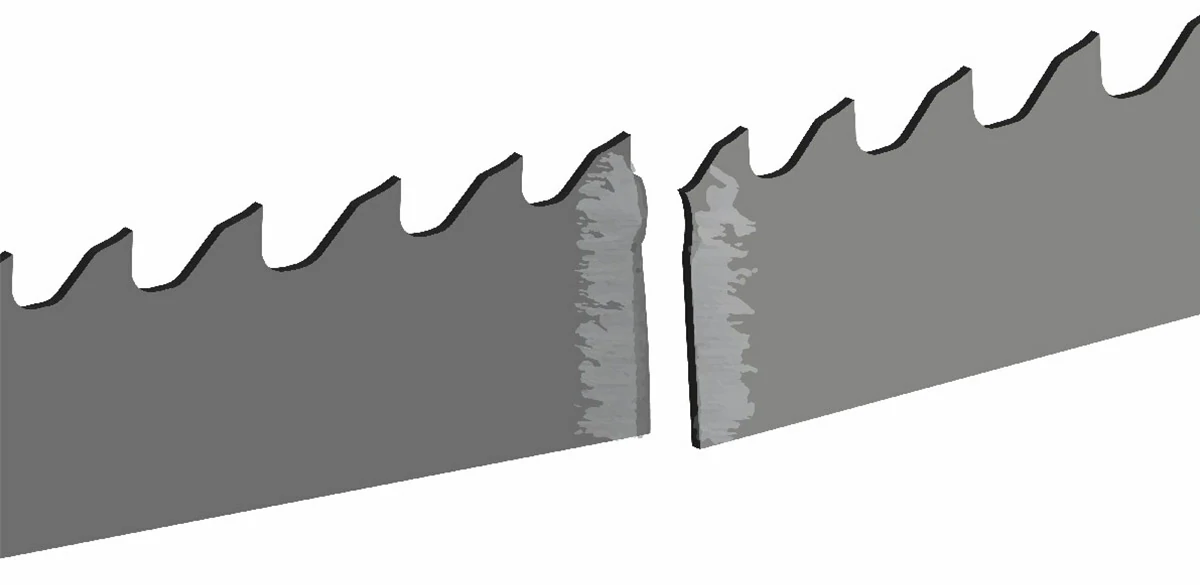

A new band saw blade has razor sharp tooth tips. In order to withstand the cutting pressures used in band sawing, tooth tips should be honed to form micro-fine radius. Failure to perform this honing will cause microscopic damage to the tip of the teeth, resulting in reduced blade life

Problem

- Incorrect Tooth Selection

- Improper Break in Process

- Excessive Band Speed

- Improper Feed Rate

- Cutting material Hardness too high

- Improper clamping of cutting material

- Coolant not sufficient

Solution

- Select proper teeth as per chart

- Follow the break in process accordingly

- Follow Band speed as per chart

- Follow Feed rate as per chart

- Increase the speed and feed

- Clamp properly before Cutting

- Check coolant ratio and flow

Problem

- Improper tooth pitch for cross-section size material being cut

- Improper Break in Process

- Improper material clamping

- Improper position of material being cut

- Improper Feed Rate

- Hard spot in cutting material

- Coolant not sufficient

Solution

- Select proper teeth as per chart

- Follow the break-in process accurately

- Follow Band speed as per chart

- Follow Feed rate as per chart

- Increase the speed and feed

- Clamp properly before cutting

- Check coolant ratio and flow

Problem

- Incorrect Tooth Selection

- Improper Band Tension

- Band speed too high

- Excessive Feed Rate

- Back-edge Rubbing with Wheel

- Guide Worn-out

Solution

- Select proper teeth as per chart

- Reduce band tension by using tension meter

- Follow Speed / Feed Ratio table

- Follow Speed / Feed Ratio table

- Set Wheel Position

- Replace Guide

Problem

- Improper Band Tension

- Guide Arm distance High

- Improper Beam Bar Alignment

- Excessive Feed Rate

- Guide pressure too high

Solution

- Reduce band tension by using tension meter

- Maintain proper guide arm distance

- Maintain proper beam bar Alignment

- Follow Speed / Feed Ratio table

- Reduce guide pressure

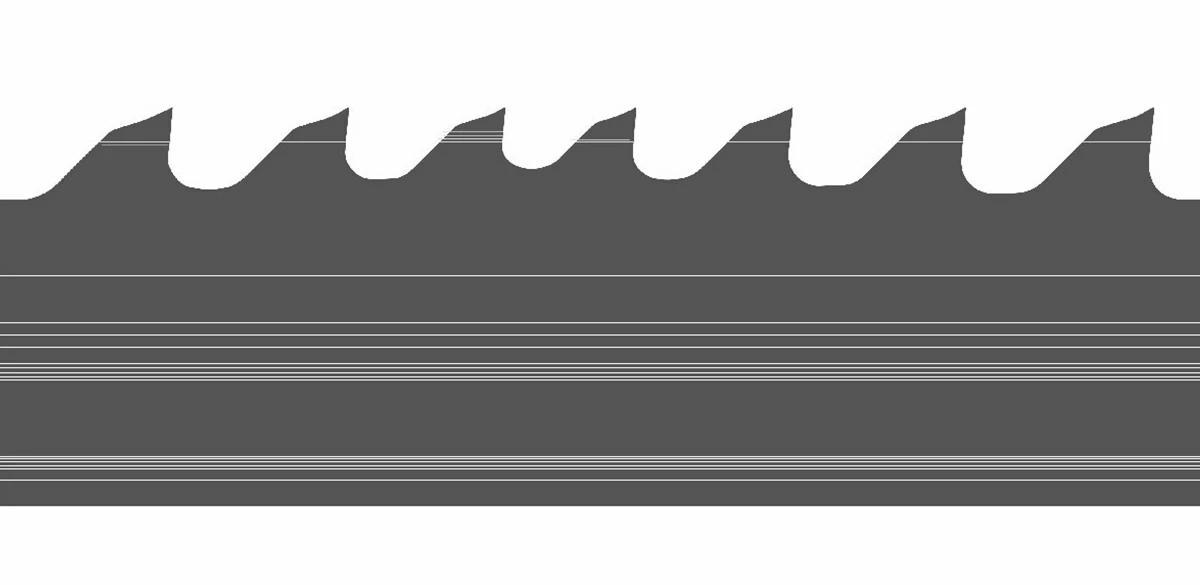

Problem

- Coolant not sufficient

- Improper Feed Rate

- Improper band speed

Solution

- Check coolant ratio and flow

- Follow Feed rate as per chart

- Follow Feed rate as per chart

Problem

- Incorrect Tooth Selection

- Improper Band Tension

- Band speed too high

- Excessive Feed Rate

- Back-edge Rubbing with Wheel

- Guide Worn-out

Solution

- Select proper teeth as per chart

- Reduce band tension by using tension meter

- Follow Speed / Feed Ratio table

- Follow Speed / Feed Ratio table

- Set Wheel Position

- Replace Guide

Problem

- Guide Adjustment is too tight

- Guide Wear / Damage

- Coolant not sufficient

Solution

- Guide to be adjusted

- Change / Replace guide

- Check coolant ratio and flow

Problem

- Excessive Band Tension

- Worn Band wheel causing uneven tension

- Side Guide too tight

- Guide Arm distance High

- Band rubbing heavy on wheel flange

Solution

- Reduce band tension by using tension meter

- Replace wheel

- Re-set guide

- Maintain proper guide arm distance

- Re-set the Wheel

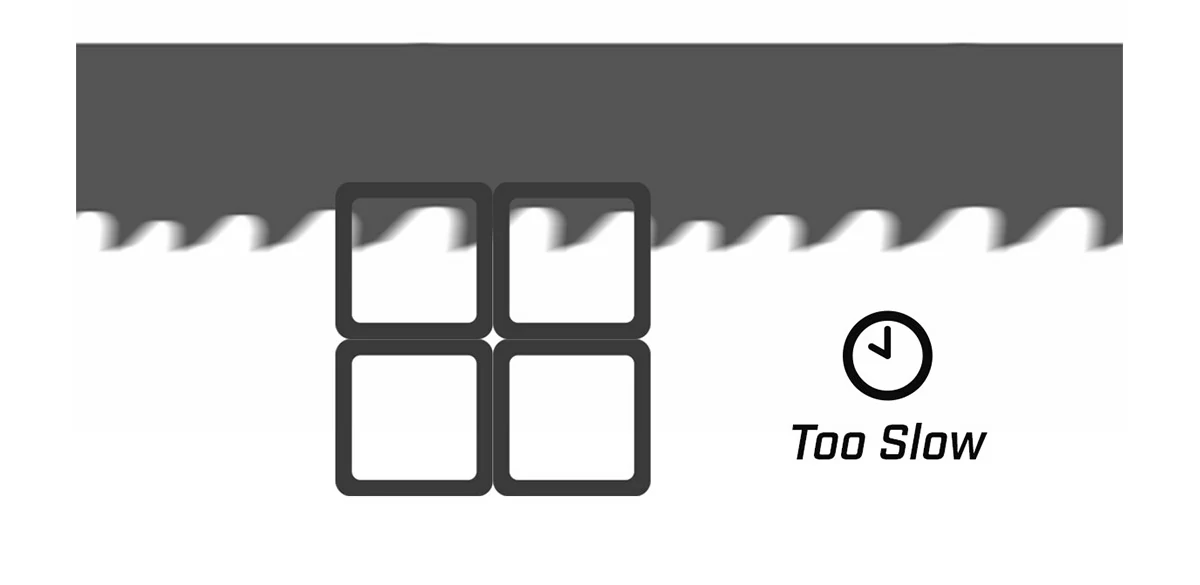

Problem

- Incorrect Tooth Selection

- Band speed too slow

- Excessive Feed Rate

- Blade life nearing the end

Solution

- Select proper teeth as per chart

- Follow Speed / Feed Ratio table

- Follow Speed / Feed Ratio table

- Replace with New Blade

Problem

- Incorrect Tooth Selection / too coarse teeth

- Band speed too slow

- Excessive Feed Rate

- Machine condition not proper / Vibration in machine

- Coolant not sufficient

Solution

- Select proper teeth as per chart

- Follow Speed / Feed Ratio table

- Follow Speed / Feed Ratio table

- Stop the machine and check all functional component

- Check coolant ratio and flow

Problem

- Incorrect Tooth Selection / too coarse teeth

- Improper band speed for cutting material

- Excessive Feed Rate

- Improper Band Tension

- Improper material clamping

Solution

- Select proper teeth as per the chart

- Follow the Speed / Feed Ratio table

- Follow the Speed / Feed Ratio table

- Reduce band tension by using a tension meter

- Clamp properly before cutting commences

We have dedicated professionals for approaching the right solution to your sawing application. We are committed to providing you on-time delivery with the best and reliable packaging, with a wide network. Consistent quality and product reliability are key to our success.

Join our mailing list for the latest updates on our brands, businesses and more.